In the fast-paced world of manufacturing, keeping track of inventory and assets can be a daunting challenge. Many organizations still rely on outdated methods such as manual paperwork, spreadsheets, or simply counting on experienced staff’s intuition to monitor stock levels and track items. While these approaches may have worked in the past, they often fall short in today’s competitive environment, where precision, speed, and cost-efficiency are paramount. Tasks like inventory counts, shipping, and locating work-in-progress items can consume valuable time and resources, particularly amid ongoing labor shortages.

This is where RFID (Radio-Frequency Identification) technology steps in as a game-changer, and Cinter Technology is leading the way with its cutting-edge RFID solutions designed to transform inventory management in manufacturing environments.

Streamlining Inventory Management with RFID

Cinter Technology’s RFID solutions bring a modern approach to inventory management by enabling automatic tracking of inventory and assets in real time. Using RFID tags, including those that are metal-compatible, manufacturers can tag individual items, boxes, or even pallets, allowing them to be tracked throughout the supply chain, from the production floor to the warehouse and beyond.

The use of RFID technology significantly reduces the need for manual inventory counts, minimizing human error and improving data accuracy across the board. In challenging environments, such as warehouses filled with metal structures and equipment, RFID tags can still provide reliable tracking, thanks to the use of specialized metal-compatible tags. This ensures that businesses can maintain accurate inventory records and monitor stock levels with minimal manual intervention.

By automating the tracking process, companies can dramatically cut down on time spent searching for inventory or verifying stock levels. This translates to faster inventory audits, reduced labor costs, and a more efficient supply chain, ultimately enhancing overall productivity.

Enhancing Asset Tracking

Manufacturing companies often struggle with keeping track of tools, molds, and other essential equipment that are critical for daily operations. Misplacing or losing such assets can lead to production delays and additional costs. Cinter Technology’s RFID solutions provide an effective way to manage these assets by tagging each item and monitoring its location in real time.

This approach not only improves visibility over the equipment’s whereabouts but also helps prevent loss and theft. It enables maintenance teams to keep better track of tool usage and ensure that equipment is serviced on schedule, further reducing downtime and extending the lifespan of valuable assets.

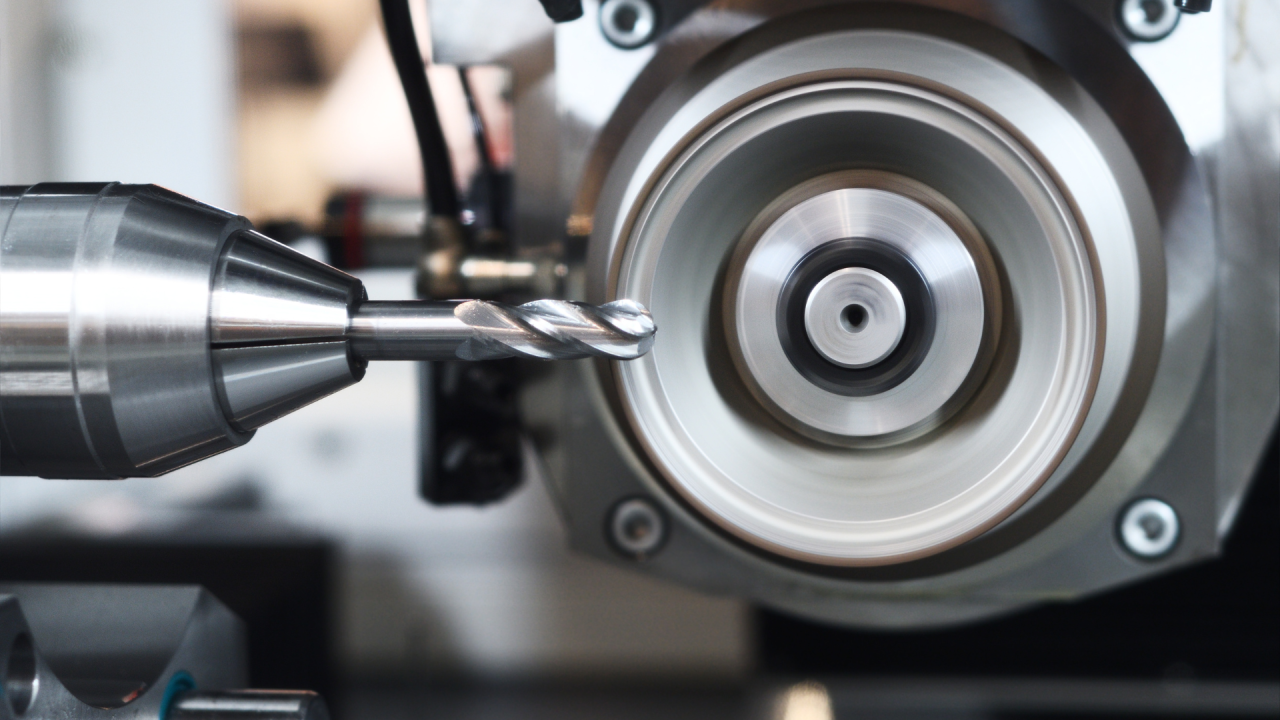

A Perfect Fit for Cutting Tool and Equipment Manufacturers

For cutting tool and equipment manufacturers, RFID technology offers a significant boost in productivity and service levels. The ability to quickly and accurately track inventory and assets ensures that the right tools are available when needed, reducing production interruptions and enhancing customer satisfaction.

As the manufacturing industry continues to evolve, adopting RFID solutions is not just a technological upgrade; it’s a strategic move that can drive business growth and resilience. By integrating RFID technology into inventory management and asset tracking processes, companies can stay ahead of the curve, optimize operations, and achieve new levels of efficiency.

Learn more about how Cinter Technology’s RFID solutions can help revolutionize your inventory management.

📧 Email: sales@technology.cinter.net

📞 Phone: (888) 273-8983

Interested in learning more about Cinter Technology and how our services can help your business?